- High precision stencil printer

- Fuji AIMEX III

- Reflow oven

- Automated Optical Inspection

- Board Handing Loader/ un Loader

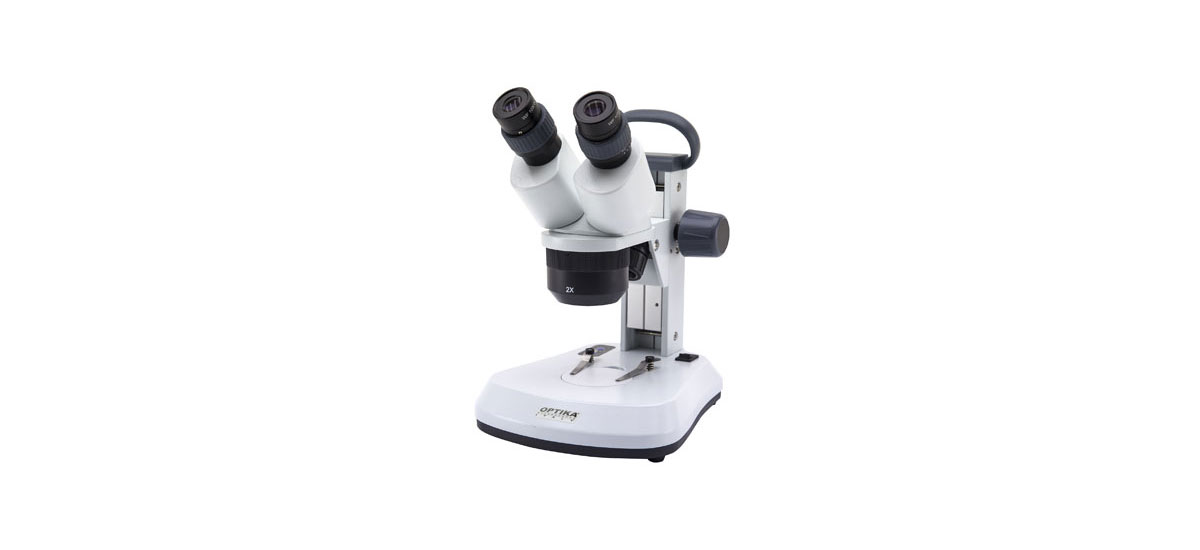

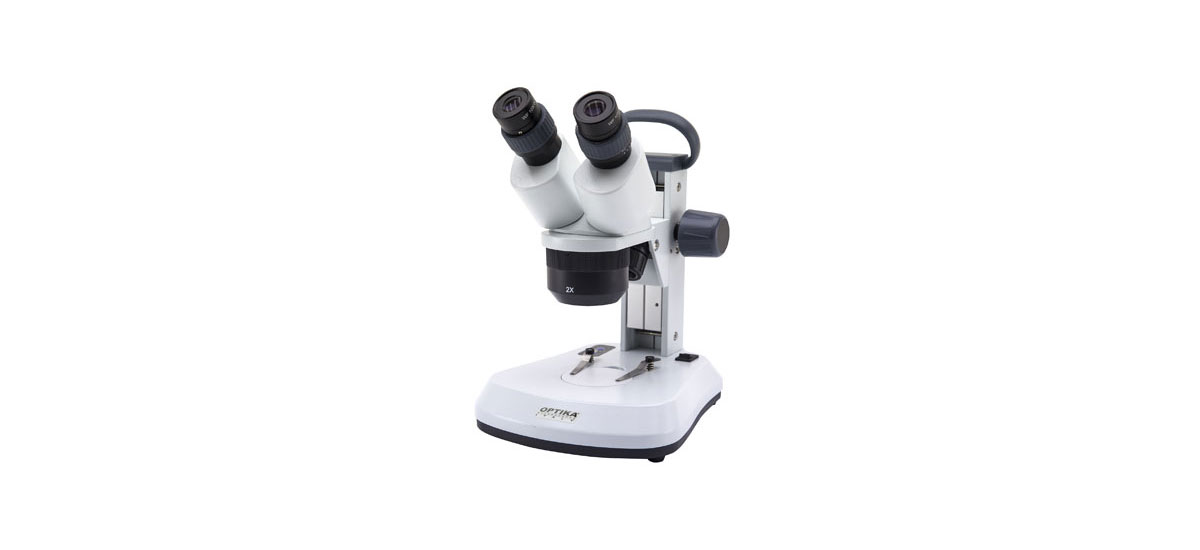

- 40X Microscope

- PCB Baking Oven

- Weller Soldering Stations

Specifications :

| Item | GPX-C |

| PCB size(L x W) | 48 x 48 mm - 610 x 610 mm |

| Printing speed | 1 - 200 mm / second |

| Screen frame compensation accuracy | +/-0.012 mm @6σ (Cpk≥2) * Under conditions at Fuji. |

| Printing accuracy | +/-0.020 mm @6σ (Cpk≥2) * Under conditions at Fuji.(Using CeTaQ's measurement system) |

| PCB load time | 7.5 sec *PCB loading / unloading, mark reading and screen correction are included. |

| Squeegee pressure control | Print feedback control: Print setting range 10 - 250 N |

| Screen frame (L x W) | 750mm×750mm, 750mm×864mm, 29inch×29inch, Width can be adjusted by the millimetre from 550 to 750 |

| Squeegee type | Double squeegee |

| Machine dimensions | L: 1220 mm, W: 1650 mm, H: 1475 mm |

Specifications

| PCB size(LXW) | 48 x 48 mm to 774 x 610 mm (double conveyor)*

48 x 48 mm to 774 x 710 mm (single conveyor) *Double conveyors can handle PCBs up to 330 (W) mm. PCBs larger than 330 (W) mm must be produced by changing the double conveyor to single lane production mode. |

|||||||

| Feeder capacity | Up to 130 (8 mm tape) | |||||||

| PCB load time | 2.9 sec | |||||||

| Placing accuracy

(Fiducial mark based referencing) |

H24G: +/-0.025 mm (Standard mode) / +/-0.038 mm (Productivity priority mode, under development) (3sigma) cpk≥1.00

H08M: +/-0.040 mm (3σ) cpk≥1.00 OF: +/-0.050 mm (3σ) cpk≥1.00 H02F: +/-0.025 mm (3σ) cpk≥1.00 H01: +/-0.030 mm (3σ) cpk≥1.00 |

|||||||

| Machine dimensions | L: 1280mm, W: 2656mm, H: 1556mm | |||||||

|

Placing heads |

||||||||

| H24G | H08M | H02F | H01 | OF | ||||

| Nozzle quantity | 24 | 8 | 2 | 1 | 1

(or 1 claw) |

|||

| Throughput(cph) | 37,000 cph (Productivity priority mode under development)

35,000 cph (Standard mode) |

13,000 | 7,300 | 4,200 | 3,000 | |||

| Part size

(mm) |

03015 mm to 5 x 5

Height: Up to 2.0 mm |

0603 (0201")

to 45 x 45 Height: Up to 13.0 mm |

1608 (0603")

to 74 x 74 (32 x 180) Height: Up to 25.4 mm |

1608 (0603")

to 74 x 74 (32 x 180) Height: Up to 38.1 mm |

||||

|

DynaHead(DX) |

||||||||

| Nozzle quantity | 12 | 4 | 1 | |||||

| Throughput(cph) | 27,000

Parts presence function ON: 26,000 |

12,000 | 5,800 | |||||

| Part size

(mm) |

0402 (01005") to 12.5 mm diagonally and Y is 7.5 mm or less

Height: Up to 3.0 mm |

1608 (0603")

to 15 x 15 Height: Up to 6.5 mm |

1608 (0603")

to 74 x 74 (32 x 100) Height: Up to 25.4 mm |

|||||

| Placing accuracy

(Fiducial mark based referencing) |

+/-0.038 (+/-0.050) mm (3σ) cpk≥1.00 | +/-0.040 mm (3σ) cpk≥1.00 | +/-0.030 mm (3σ) cpk≥1.00 | |||||

Specifications :

| Dimensions | 5378(L) x 1320(W) x 1490(H) mm |

| Number of heating zones | 8 top, 8 bottom |

| Length of heating zones | 3110 mm |

| Number of cooling zones | 2 top |

| Length of cooling zones | 800 mm |

| Electric supply | 3 phase, 380 V 50/60 Hz (Option: 3 phase, 220 V 50/60 Hz) |

| Total power | 67 kW |

| Starting power | 32 kW |

| Normal power consumption | 10 kW |

| Warming time | Approx. 30 minutes |

| Temp. setting range | Room temp - 300°C |

| Temp. control method | PID Close Loop Control + SSR Driving |

| Temp. control precision | ± 1.0°C |

Board Dimensions SJ50 Series 3

- Minimum board size : 50mm by 50mm(2”by2”)

- Maximum board size : 510mm by 510mm(20”by20”)

- Maximum board thickness : 4 mm (0.16”) 15 mm (0.5”)

- Board weight Up to 3 kg (6.6 lb) Up to 13 kg (28 lb)

- Maximum board size for dual

- lane conveyor hardware option : 216 mm by 510 mm (8.5” by 20”)

- Maximum board thickness : 4 mm (0.16”)

- Minimum board thickness : 0.5 mm (0.02”)

- Board weight : Up to 3 kg (6.6 lb)

Software Systems

- Operating environment : Windows ® XP SP2 operating system with easy to use GUI and password- protected user levels

- Vision Algorithms : Parametric component models, self learning classifiers, color learning, geometric pattern matching, solid shape modeling (SSM)

- Statistical Analysis : Supports Agilent’s proprietary SPC and defect prevention packages, complete with test output files.

- Data transfer interface : 3.5” FD, DVD/CD-RW, USB drives, and Ethernet

Functionality

- Post-reflow inspection : Coverage: Missing, offset, skewed, polarity, billboard, tombstone, lifted/bent leads, excess/insufficient solder, bridging, wrong part, and traceability

- Speed of inspection. : Post reflow: 5 in2/sec (32 cm2/sec) Pre-reflow: 6.3 in2/sec (41 cm2/sec)

- Traceability Board level Component level : External barcode reader configured; camera-read barcodes OCR capability with batch code logging

Specifications :

- Touch Screen (Operating panel)

- Tower Lamp

- Manual width adjustment

- Double Plate structure

- SMEMA Interface

- Controlled by PLC

- Pitch selectability

- Magazine rack 50 Slots